Description

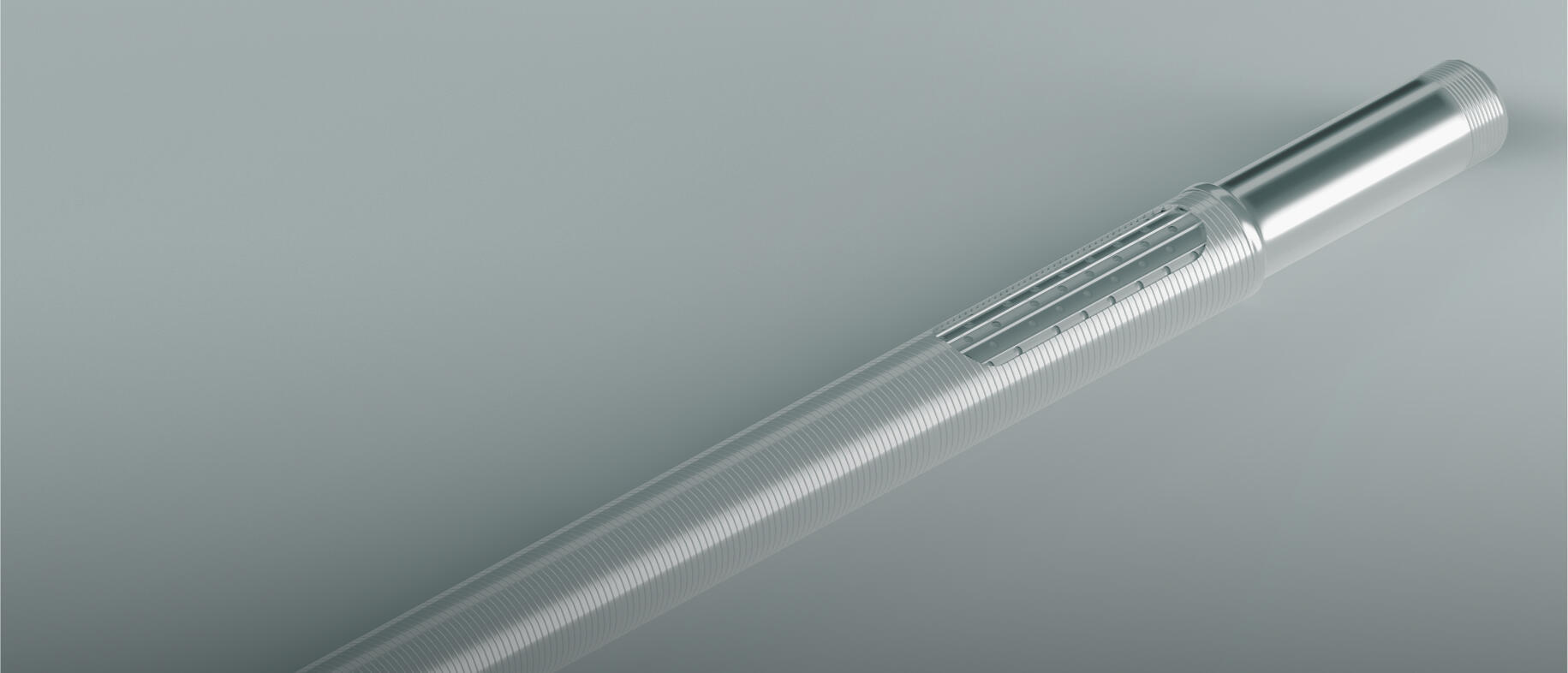

AlfaDirect is a robust and reliable direct wire wrapped sand screen. Due to the direct winding technology, the highest requirements for wire wrapped sand screens are ensured. This is achieved by wire wrapping with welding in each rods contact points.

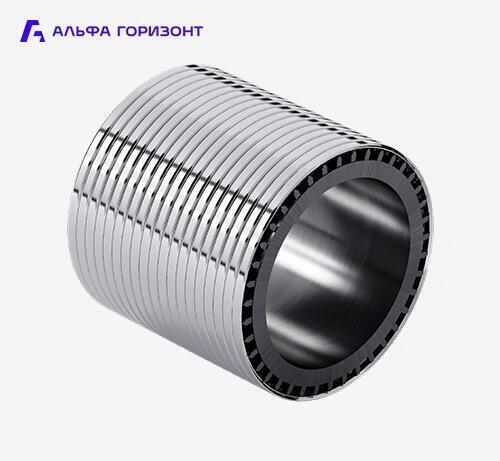

The slot size of the direct wire wrapped screen can vary from 100 to 2000 microns. In this case, the tolerance is controlled in the size of the gap about ±25 microns.

The presence of a drainage layer between the wire wrapped screen and the base pipe ensures uniform flow of fluid along the surface of the base pipe and reduces the risk of filter sticking.

The direct wire wrapped screen has a higher strength than other types of screens because it is wound directly onto the base pipe.

Due to the high resistance of the DW screen to rotational loads and compression, it minimizes the risk of damage during RIH and rotating.

Parameters

- Base pipe range: 73-178 mm;

- Screen length: up to 9500 mm;

- Slot size: from 100 to 2000 microns;

- Drainage layer height: from 1,5 to 6 mm;

- Material of filter element and end ring: stainless steel AISI 304L, 316L, 321;

- Welding of the wrapped wire at each point of contact with the rod wire;

- Tearing force of wrapped wire: at least 130 kgf;

- Possibility of liner rotation during the descent;

- Working temperarture: from -50 to +200 C.

Usage

Advantages

- Ultra-high durability to minimize the risk of damage during RIH and rotating;

- High precision slots for high quality filtration;

- Stainless steel parts with AISI 304L/316L/321 makes the screen resistant to corrosion and high temperatures;

- Triangular wire profile contributes to the filter's resistance to sticking;

- Variability of drainage layer height for different well conditions.