Description

It is a direct wrapped sand screen AlfaDirect for completion in a liner, capable of autonomous blocking unwanted fluid (water, gas) during production. AlfaDirect AICV® can be retrofitted with chemical inflow indicators to monitor well performance without additional logging of the well using coiled tubing, cable or a down-hole tractor. To be able to stimulate the well, the device can be equipped with an injection valve. The AICV® technology is developed by InflowControl, autonomously reduce unwanted water or gas breakthroughs, aligning the inflow profile along the wellbore, delaying and minimizing the risks of coning in highly permeable reservoirs.

This device allows to automatically cut off the ingress of unwanted fluid in the form of water and gas into the production well. The AICV® device is designed to prevent the negative effect of water and gas breakthrough and increase the oil recovery factor when used in difficult heterogeneous reservoir conditions with fault zones and zones of highly permeable formations of the field.

The AICV® works autonomously and does not require external control. When isolating well intervals using packers, the AICV® device allows to completely shut off the inflow of gas and water in a certain section ("zone") of the well. At the same time, the inflow of produced oil continues from other zones of the well, which are not affected by gas breakthrough, which optimizes oil production and recovery.

The AICV® is also reversible, allowing oil to resume flow once oil begins to flow at the device inlet and water or gas breakthrough conditions cease.

The AICV® is supplied with a wire sand screen. The inflow control device is mounted on the wall of the base pipe at each connection, by analogy with the installation of standard ICD devices. The AICV is mounted on the outer end of the sand filter and forms part of the complete unit. The device itself, in addition to the valve, also includes a module that provides fluid supply to the valve and connects it to the outlet of the sand filters.

The valve technology is based on the use of the effect of differential pressure for different fluid flows (laminar and turbulent) depending on the viscosity, density and flow rate. When installing AICV® in a completion system, it is common to isolate different segments of the well with swell able packers so that the AICV® can control fluid inflow by segment (zone) and minimize unwanted fluid inflow.

Purpose

Characteristics

- Available for base pipes in a wide range of sizes of 73 - 168 mm

- Sreen length up to 9000 mm

- The size of the slot hole is from 100 to 2000 microns

- The drainage layer height is from 1.5 to 6 mm

- Valve material - tungsten carbide

- The maximum valve overlap for water is 99%, 98% for gas.

- The best autonomous inflow control device ever made

Usage

Advantages

- The key benefits of the new generation AICV device are that it uses the main advantages of the previous ICD models and solves the problem of inflow control more efficiently.

- Guaranteed to prevent water and gas breakthrough into the well;

- Does not require external management, remote control;

- The device restores the flow of oil after blocking the breakthrough of water or gas;

- Has no limitation on the number of zones in the well to which the device can be installed;

- Has the best performance indicators compared to traditional AICD;

- Can be installed on new and existing wells.

Scheme of work

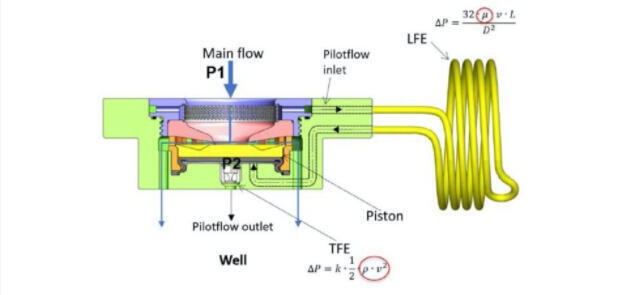

The main feature of the AICV device is the separation in the total fluid flow through the device of an auxiliary channel or sleeve, through which only 1% of the total flow passes through this device.

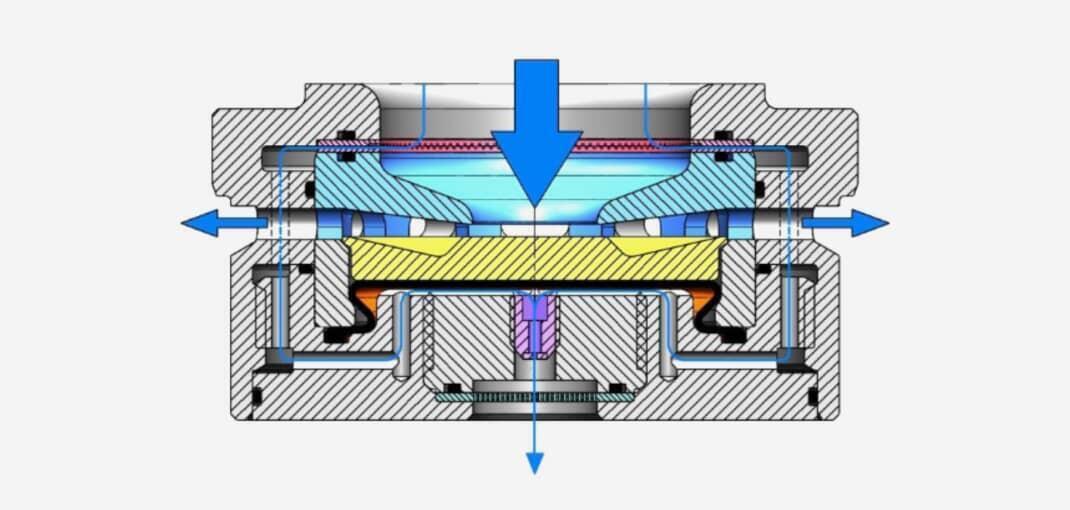

This channel is used to control the valve for opening the main channel of the fluid inflow. The fluid flow entering the valve is split into two channels: main and auxiliary.

The main channel contains a movable valve, the degree of opening of which is regulated by the force of the piston, which in turn depends on the pressure in the auxiliary channel. Two limiters are installed in the auxiliary channel, the first of them forms a laminar fluid flow, the second is a nozzle through which a turbulent fluid outflow occurs. The movable piston allows the valve to be closed in the main channel.

The setting of the valve position is determined by the pressure difference in the channels of the device, in the case of oil the valve is open, in the case of water and gas the pressure on the piston increases, the valve closes and the flow of water or gas is blocked.

Fluid flow is directed radially from the reservoir through a sand screen around the base pipe, along the outside of the pipe, through the annulus, to the inlet of the AICV and further into the production string. When gas or water reaches the annulus in one of the zones of the well, the AICV in that zone is closed.

The optimal configuration and distribution of AICVs depends on the site where they are installed.