Description

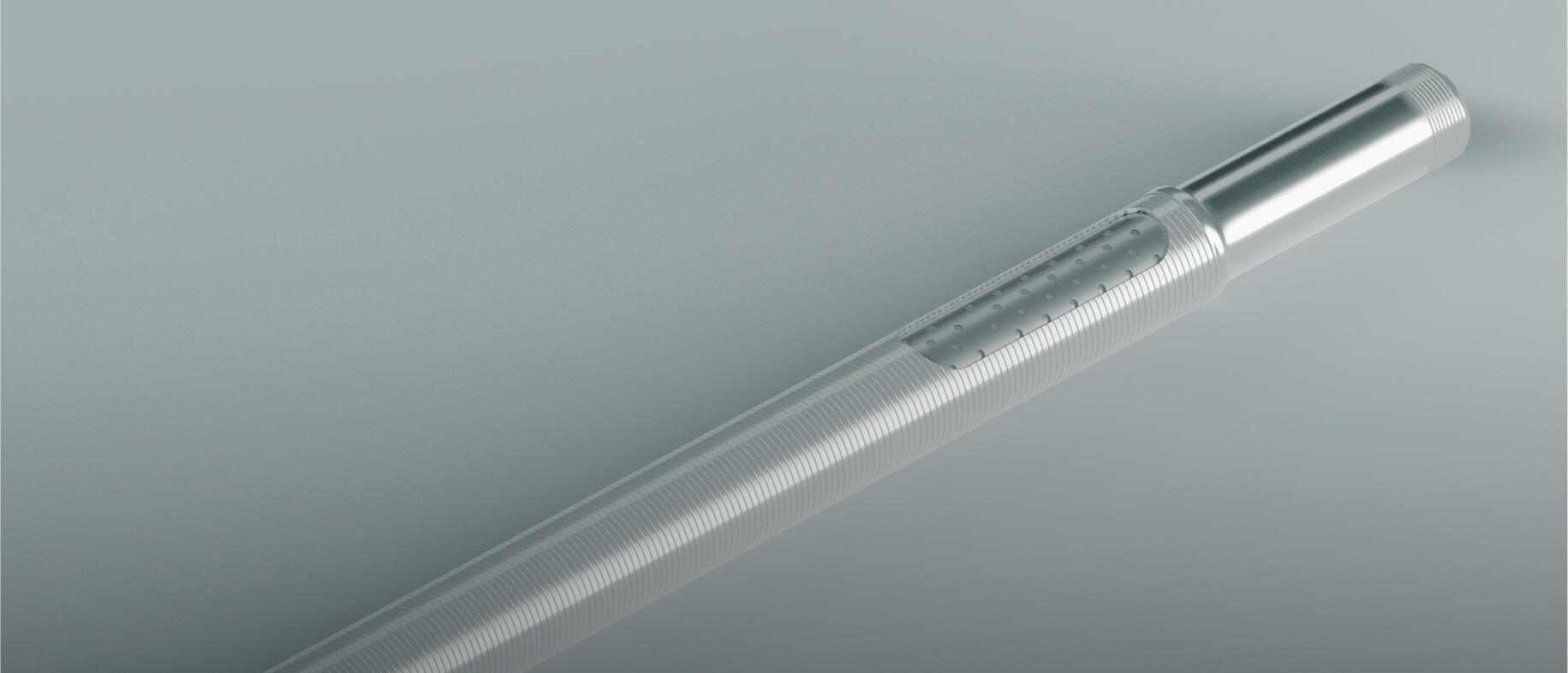

AlfaShell is a slip-on wire wrapped sand screen, which is used in oil and gas wells in order to increase the life of the well and down-hole equipment, as well as in conditions of a variable chemical composition of the produced, when there is a risk of corrosion and sticking of ferrous and carbonate deposits, since the screen restores its operability after regeneration (flushing, acid treatment).

AlfaShell is a down-hole slip-on sand screen designed for oil and gas wells from 100 microns in size. The cheapest wire sand screen with optimal parameters.

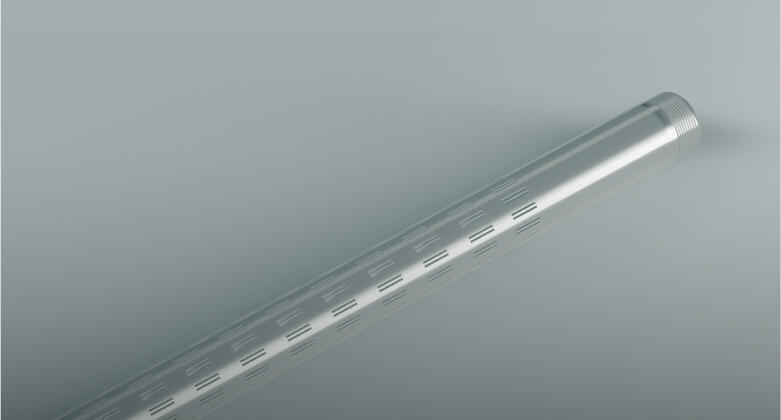

The filter construction includes a wire mesh in the form of a Johnson slit screen, which is fixed to a perforated base pipe.The screen has a cylindrical structure made of profiled steel of triangular cross-section and supporting bearing elements (longitudinal elements or stringers), which are connected by welding at each points of contact. The screen is secured to the perforated base pipe using closing rings. The points of contact are welded. The filtration quality is determined by the size of the gap, which is determined using the granulometric analysis data of the composition of formation rocks sand particles.

A special feature of the AlfaShell wire filter is the high precision of the wire screen slotted holes, which is achieved by using precision welding machines and a production quality control system. In order to safely run the sand screen into the well, a technology can be used to protect the base pipe perforations from premature fluid penetration into the well. This technology is based on the use of special sealing caps, which are pressed into the base pipe and prevent the flow of fluid. After installing the liner, the caps are cut off with a special tool inside the base pipe or removed by flushing the well with a hydrochloric acid solution.

Parameters

- Slip-on wire wrapped sand screen;

- Base pipe range: 73-178 mm;

- Screen length: 1000-8000 mm;

- Slot size: 100-2000 microns;

- Material of filter element and end rings: stainless steel AISI 304L, 316L;

- Welding of the wrapped wire at each point of contact with the rod wire;

- Standard perforations: 10-16 mm* (or at the Customer's request).

Usage

AlfaShell is used in oil and gas wells in order to increase the service life of the well and downhole equipment. This type of screen is used in conditions of variable chemical composition of the production fluid, when there is a risk of corrosion and sticking with ferrous and carbonate deposits, since the screen restores its operability after regeneration (flushing, acid treatment).

Benefits

- The optimal and variable open area of the screen allows to increase the well flow rate and reduce the compression pressure on the screen surface;

- High accuracy of the slot size, tolerance ± 25 microns;

- Variable shape and a large number of supportive rods ensure high strength of the screen in the axial and radial direction;

- Stainless steel AISI 304L/316L makes the screen resistant to corrosion and high temperatures.