Introduction: Slot inspection machine API Q1

2020

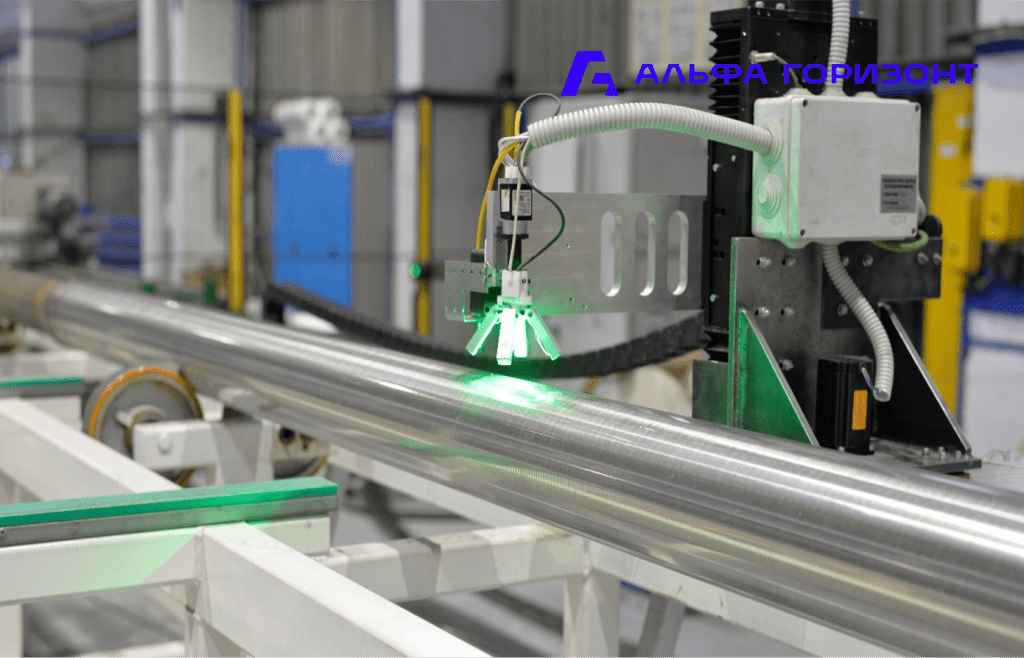

At the production site in St. Petersburg, the AlfaInspect inspection machine for laser-optical inspection of the slotted gaps of direct winding filters has been successfully tested. The inspection machine developed in cooperation with Kvantron company allows automatic scanning of the surface of finished filters in order to check the quality of the slotted gaps execution. The machine has a system of horizontal and vertical movement, which makes it possible to measure slotted gaps along filters up to 10 meters long. The accuracy of the slotted holes measurements is checked on reference winding samples, which undergo an independent examination of the gaps in certified centres. Testing programs can significantly increase the speed and accuracy of checking slotted gaps relative to manual control. This project is the first implementation in Russia of an inspection machine for automatic laser-optical inspection of filter gaps.