Description

As part of the product quality control program for tensile, rotating, bending mechanical stresses, product strength tests are carried out. Mechanical strength testing is one of the main activities of the company's research laboratory. The tests task is to check the loss of control of sand production under shear loads on tension, compression of the elements of the filter structure, to determine whether the filter loses the declared size of the slot. All these tests can be performed on one power test rig. Filter layout strain tests verify the integrity of the following filter designs:

The filter slots must maintain the basic filter values under load at nominal deviations. All mechanical tests are carried out in accordance with the enterprise TS and GOST 32504-2013

Let's highlight the main types of tests performed:

Pull test

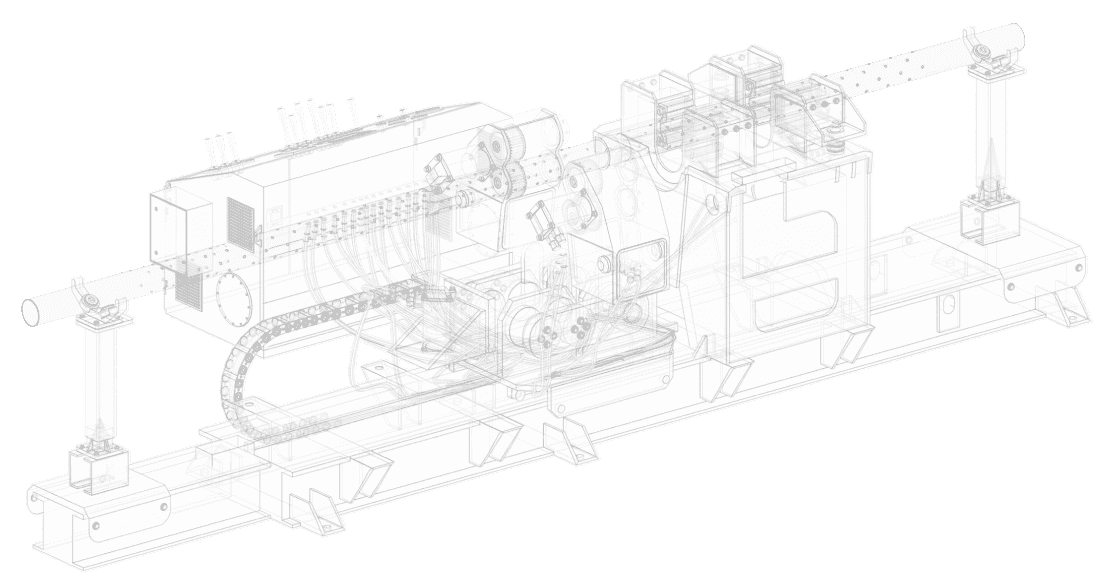

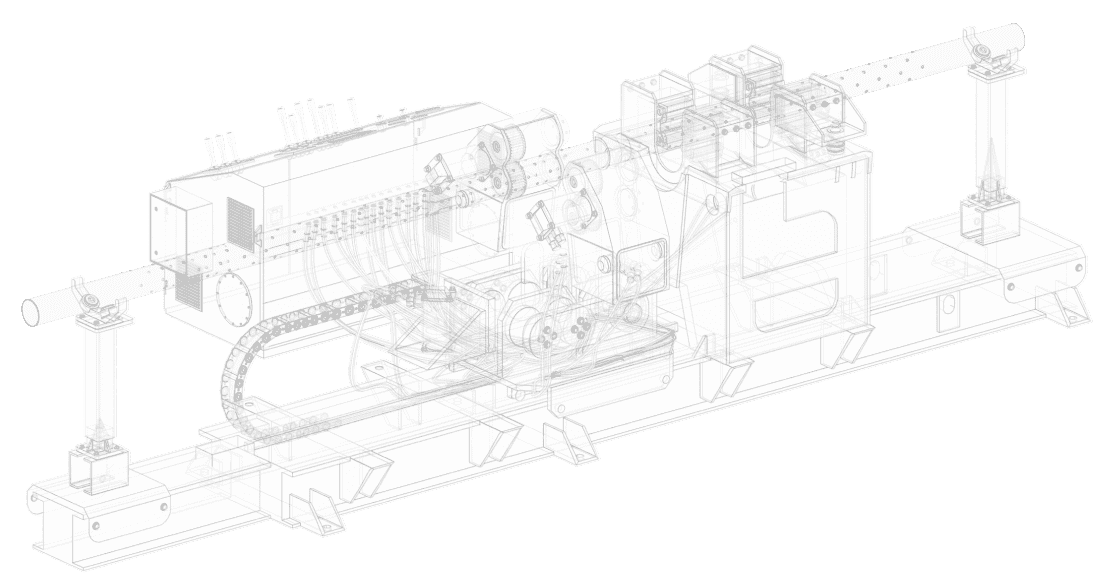

The purpose of this test is to confirm the integrity of the slotted gaps of the wire-wound filter, longitudinal stiffeners strength under the axial tensile force of the filter. This test is performed by grouting the filter section at one end and applying tensile force to the base pipe at the opposite end as shown in the figure below.

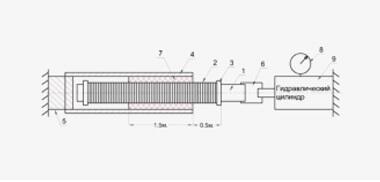

Scheme of filter cementing during tension tests. 1 - base pipe, 2 - wire winding, 3 - end ring, 4 - cementing casing, 5 - support element, 6 - hydraulic cylinder sleeve, 7 - cement mortar, 8 - pressure gauge, 9 - hydraulic cylinder.

Criterion of acceptability: the filter must withstand a voltage of 108 kN (11,000 kgf)

End ring shift test

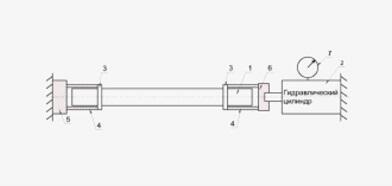

The purpose of this test is to confirm the strength of the snap ring weld to the base pipe under axial compressive force on both sides of the snap rings. The test is performed by axially displacing the rings to ensure full contact around the rings

1 - base pipe, 2 - hydraulic cylinder, 3 - retaining ring, 4 - thrust sleeve, 5, 6 - support elements, 7 - pressure gauge

Criterion of acceptability: the structure integrity must be maintained at. tension of 108 kN (11,000 kgf).

Wire push-off test

The purpose of this test is to check the weld quality of wire wound and stiffeners. The test is carried out by applying a force to the wire wound element while securing the filter element rest.

Test bench for wire wrapping compartment - stiffeners

The test bench is an installation that allows you to perform operations to separate the winding wire from the stiffeners using a press. The test requires the preparation of special samples of the wire filter by cutting out a portion of the filter surface that includes several stiffeners and a portion of the winding wire welded to them. The specimen is secured to the bench so that the punch of the press can exert pressure on the wire element to result in the separation of the winding wire from the stiffeners.

Criterion of acceptability: with a tensile load of 1.23 kN (125 kgf), the welded joint of the wire and stiffener does not break apart.

Structural bending tests

The filter must withstand the allowable deflection of the filter axis. The test method consists in fixing the filter housing by means of accessories and applying a vertical load to the end of the base pipe until the required deflection of the pipe axis by a given angle value is achieved. After load shedding, the integrity of the filter structure and its slots parameters are checked. The test should not deform the filter.

Bending test of filters Criterion of acceptability: permissible bending value / 30.5 m (/ 100 ft) or the corresponding bending angle of the structure in proportion to the length of the filter structure test section.

Torque test

Tests are conducted to verify the loss of sand control under torsional loads. Torsional loads are generated during the rotation of the liner into the well.

During the test, the filter is fastened and the torque is applied to the base pipe on which the filter is mounted. The test determines the strength of the filter binding to the base pipe when a torque of the filter rotation occurs

Criterion of acceptability: The nominal value of the load moment at which the filter construction is maintained is 8 kN * m.