Description

Hydraulic tests are conducted to confirm the strength and flow characteristics of lower completion equipment at high ambient pressures. A special hydraulic high pressure chamber is used to carry out the hydraulic tests.

The main hydraulic tests are the crush and rupture strength tests of filters. These tests are described in detail in the GOST 32504-2013 standard.

Filter hydraulic crush test

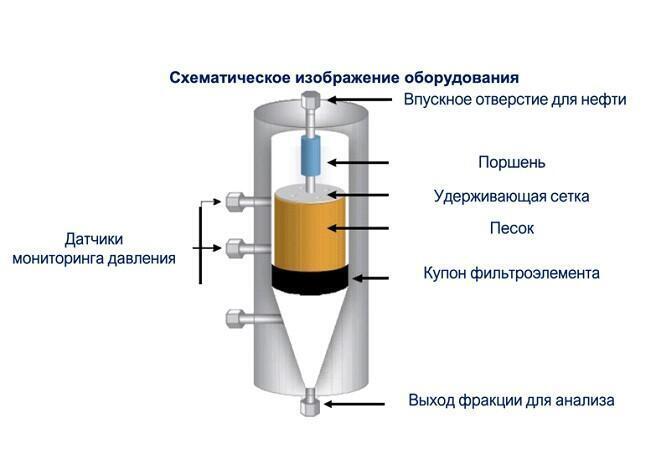

The main task of the test is to check the filter strength with a large pressure drop across the filter from the outside. To simulate this situation, fluid loss control pill by a filter is used, including the solid phase of calcium carbonate particles and fresh water. The particles are used to clog the filter surface, i.e. clogging or sticking of the filter surface. The bench has a high pressure test chamber in which the filter is fixed. The fluid loss control pill pressure is supplied from the outside of the filter. When the external pressure load critical for the filter is reached, the filter crushes (compresses, collapses).

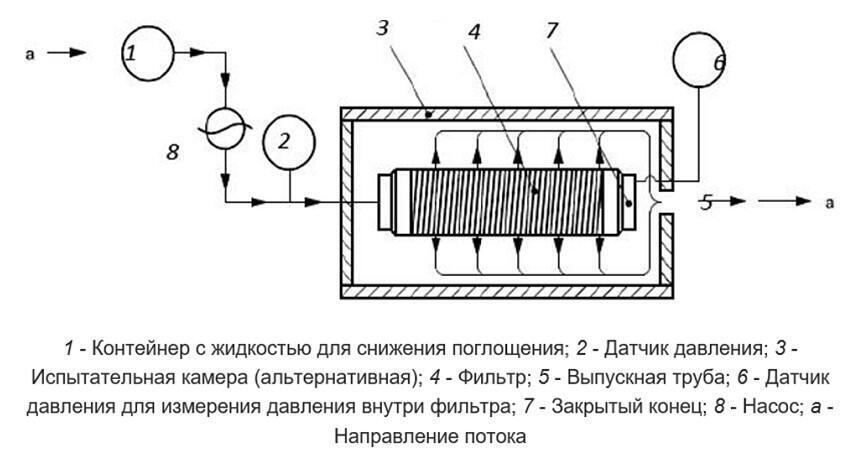

Scheme of work of the bench for hydraulic tests for crush pressure.

Criterion of acceptability: differential pressure drop that the filter can withstand must be at least 25 MPa.

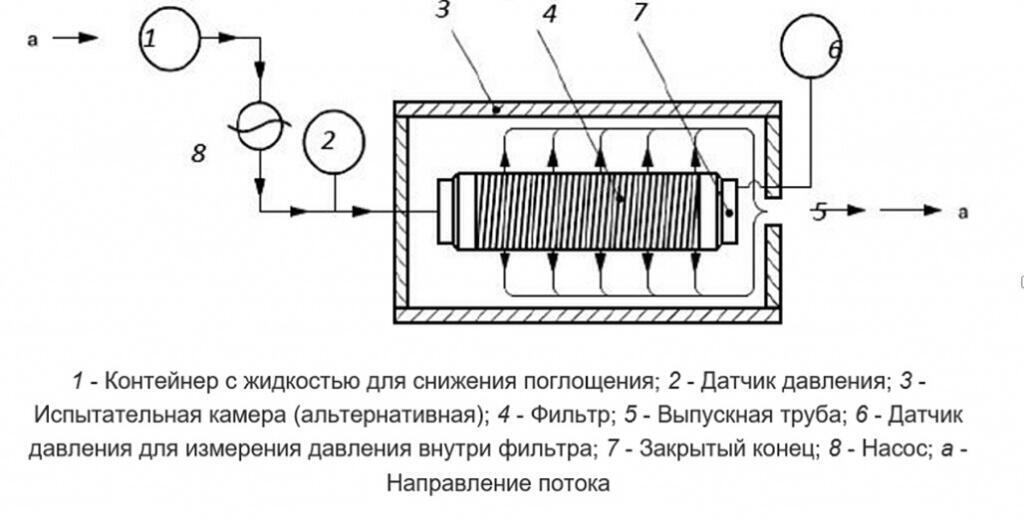

Filter hydraulic rupture test

The purpose of the hydraulic rupture test of the filter is to check the strength of the filter with a large pressure drop across the filter from the inside. To simulate this situation, fluid loss control pill by a filter is used, including the solid phase of calcium carbonate particles and fresh water. The particles are used to clog the filter surface, i.e. clogging or sticking of the filter surface. The bench has a high pressure test chamber in which the filter is fixed. The fluid loss control pill pressure is supplied from the inside of the filter. When the external pressure load critical for the filter is reached, there is a violation of the filter integrity (rupture) or drastic changes in the parameters of the filter slits.

Scheme of work of the bench for hydraulic tests for rupture pressure.

Criterion of acceptability: differential pressure drop that the filter can withstand must be at least 10 MPa.

Filter flow test or sand retention tests

The test is used to evaluate the filter through capacity parameter. Usually, the value of the open filter surface is used for this evaluation. However, a number of other parameters affect the filter's permeability, such as the thickness and number of filter layers.

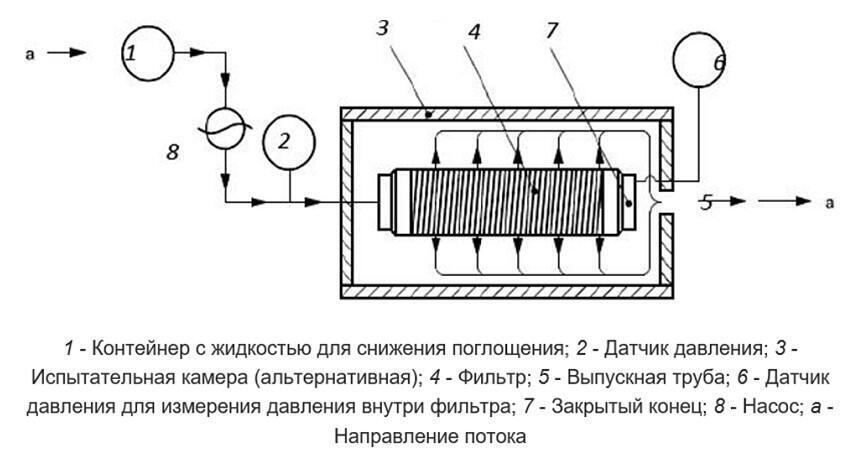

The permeability test is an important criterion for the selection of filters to assess the feasibility of their application in the specific conditions of an oil or gas field. The test is based on the dependence of the fluid flow through the filter from the flooded tank on the pressure drop across the filter: , Where μ is the flow coefficient, Q is the flow rate of the liquid through the filter, ΔP is the pressure drop through the filter, ρ is the density of the liquid, η is the duty cycle of the filter, S is the filter surface, η S is the open surface of the filter.

According to this formula, the condition of the filter through capacity will be determined by a quantity , called the hydraulic parameter of the filter. The task of the test is to experimentally determine the hydraulic parameter. The larger the hydraulic parameter, the more capacity the filter has The test is carried out on a clean, uncontaminated filter. The test bench can use a hydraulic high pressure chamber that is described in the filter crush and rupture hydraulic tests. During the test, a constant pressure drop is created in the chamber across the surface of the filter, so that a liquid flow passes through the filter from the outside. When the defined pressure drop is reached, the flow rate of the liquid through the filter and, accordingly, the hydraulic parameter of the filter are recorded. The tests are carried out for the following pressure drop across the filter: 0.05, 0.1, 0.15 MPa.

Criterion of acceptability: the test determines the value of the hydraulic parameter, as well as the fluid flow through the filter, determines the relative efficiency of the filter.

The test reveals the following characteristics

Filter bandwidth test setup scheme